News & Events

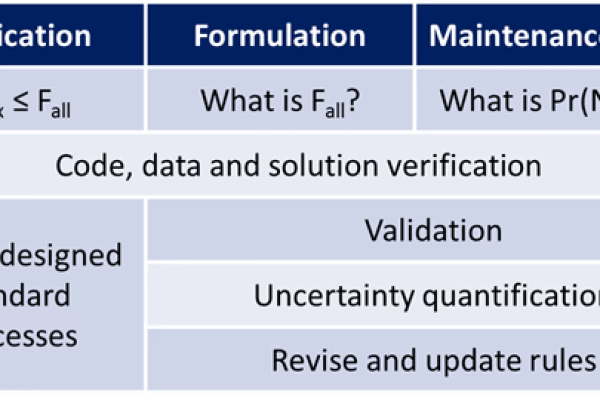

Mathematical models have become indispensable sources of information on which technical and business decisions are based. It is therefore vitally important for decision-makers to know whether relying on the predictions of mathematical models is justified. When properly used, numerical simulation can be a major corporate asset. However, it can become a major corporate liability if the reliability of predictions is not guaranteed. Learn more in our latest blog post.

Some years ago, I attended a meeting of senior engineers at a Fortune 100 company. The topic of discussion was: What should be done about the significant discrepancies between outcomes predicted by finite element models and those observed in physical tests? The chief engineer, who called the meeting, vented his frustration, declaring he was tired of hearing that the finite element mesh was the problem. He no longer believed the predictions from finite element modeling and had lost confidence in the engineers who produced those results. How could this have been prevented?

In one of my conference presentations, I discussed variational crimes, noting that using point forces and point constraints in finite element analysis serves as examples of such crimes. In the question-and-answer session, I was asked: “If using point constraints is a variational crime, then how is it possible that the structure designed to refloat the Costa Concordia was full of those crimes and yet it worked just fine.” This question presented an opportunity for me to explain that finite element modeling (FEM) and finite element analysis (FEA) are complementary methods when analysts correctly understand their respective domains of application and use them accordingly. However, problems arise when FEM is used outside its scope, which is an all too frequent error.

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989