- From the perspective of engineering leadership, StressCheck Professional is the only FEA tool that supports Simulation Governance.

- From the perspective of analysts, StressCheck Professional is the only FEA tool that supports solution verification in practical engineering settings.

- From the perspective of designers, StressCheck Professional provides a framework for standardization of routine design procedures with guaranteed reliability.

StressCheck Professional

Would you like to evaluate StressCheck?

To obtain a no-cost, 30-day evaluation of StressCheck Professional, please complete our Request a Trial Evaluation form and we’ll reach out with more details.

What is StressCheck Professional?

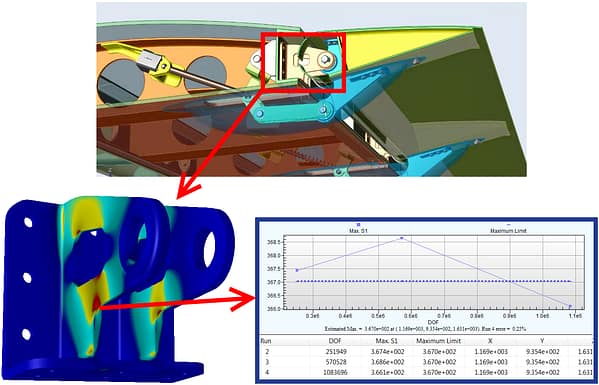

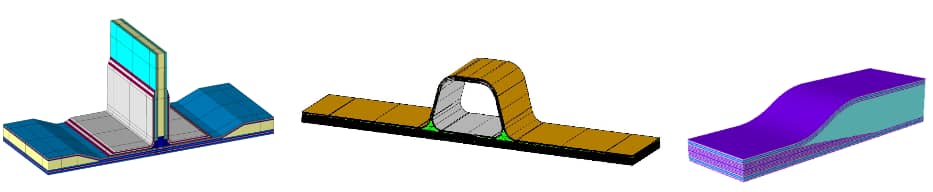

Productivity tools are available to import NASTRAN bulk data file meshes and CAD geometry, perform 2D and 3D automatic meshing, automate analyses via StressCheck’s API, and more.

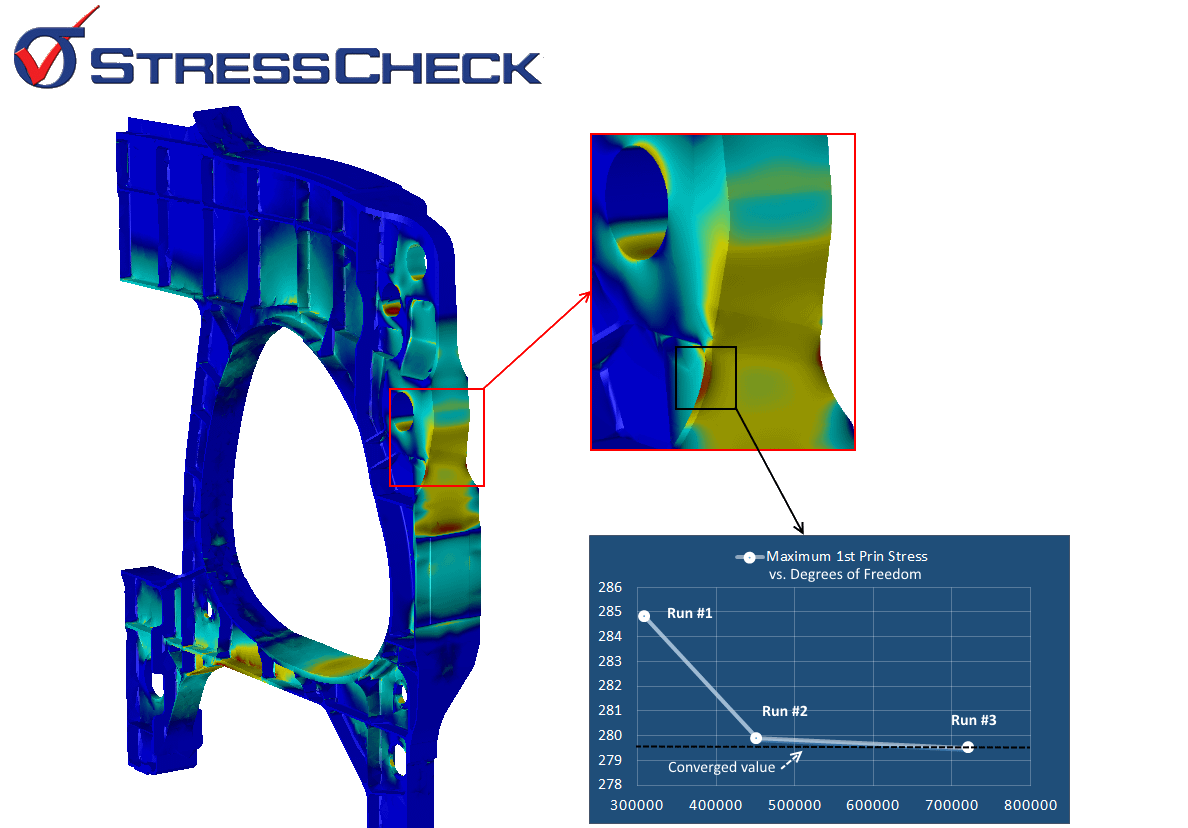

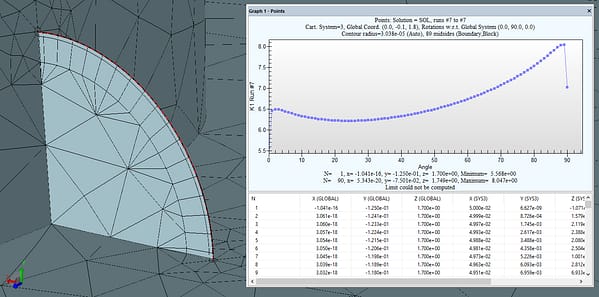

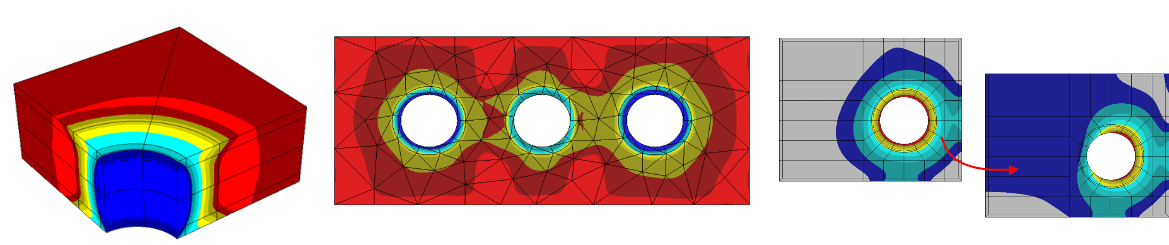

StressCheck Professional provides industry-leading live dynamic results processing options which include error estimators for the assessment of the quality of model approximation: global error estimation in energy norm and local error estimators for any engineering function of interest. Additionally, live extractions of stresses, strains and even combinations of engineering functions can be made anywhere in the model, at any time, at any resolution.

What does this all mean? Users need not spend excess time on meshing the model according to traditional FEA schema or planning ahead for myriad post-processing needs; StressCheck’s implementation provides the flexibility to account for changing requirements in engineering analysis results, all within the same model and mesh.

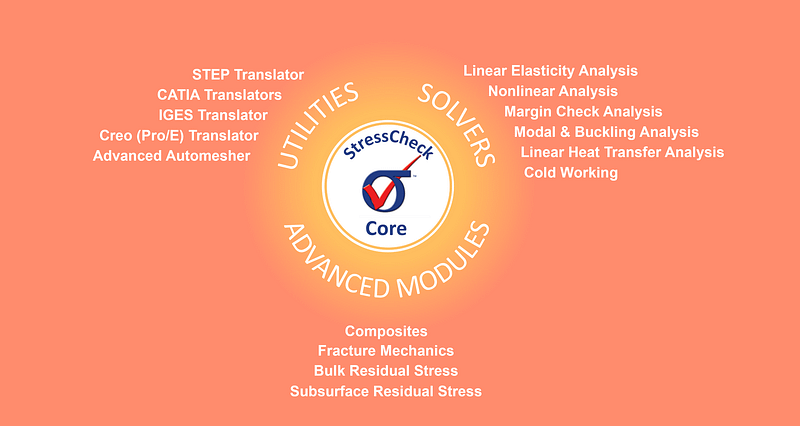

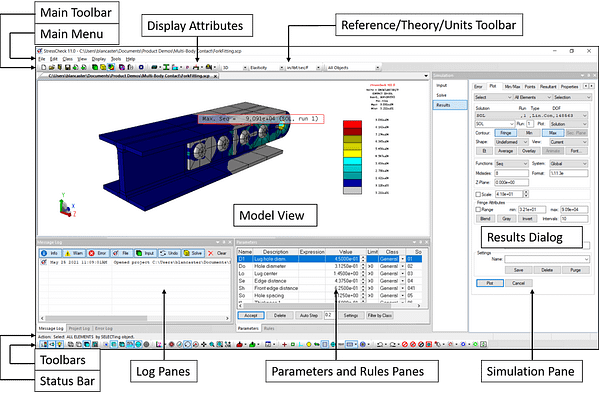

StressCheck Core is the primary building block of StressCheck Professional. It includes the 64-bit graphic user interface (GUI) and features a complete pre- and post-processor built around a parametric handbook framework that supports standardization of design and analysis processes.

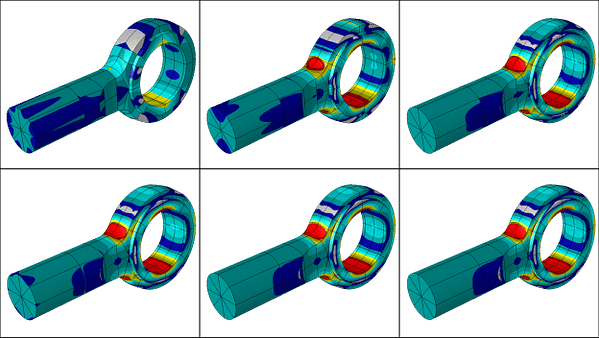

StressCheck Professional supports a wide variety of solvers, including linear (with or without multi-body contact), nonlinear (material and large deformation), modal/buckling, steady state heat transfer, and more.

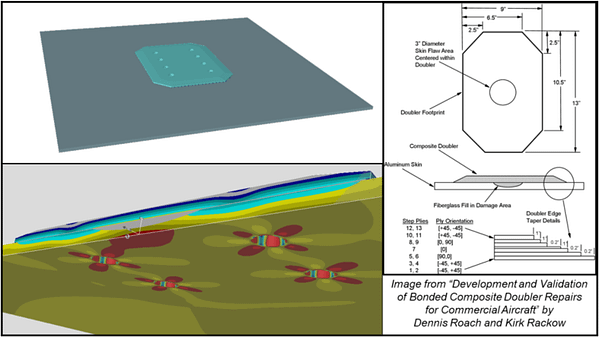

StressCheck Professional has advanced modeling capabilities in the areas of composites, fracture, residual stress and more. These are the StressCheck Advanced Modules, each module independently licensed as add-on modelers. Many of the features in these modules may even be combined together in a single model for more sophisticated FEA needs.

StressCheck‘s add-on Utilities include the latest CAD translators and advanced automatic meshing tools, in addition to the native Parasolid CAD modeler and automatic meshing tools available in StressCheck Core, to save you time and efforts in the FEA modeling process.

“StressCheck’s quality control features have given us the tool we need to perform detailed … bonded joint analysis with confidence that the results are accurate.” “… StressCheck has greatly improved our ability to accurately predict the fatigue life of joints with interference fit fasteners and cold worked holes” – The Boeing Company

Why Switch to StressCheck Professional?

StressCheck Professional represents the latest generation of FEA Simulation Technology. Watch this video to learn why you should consider StressCheck over legacy FEA for high-fidelity analysis:

StressCheck Professional is the only FEA tool currently on the market that provides S.A.F.E.R. Simulations:

Simple: Focus on your simulation requirements, and not costly decisions like selecting the “right” element types, using the “best” element size or designing meshes around post-processing areas of interest. Engineers should be doing engineering, not worrying about the mesh.

Accurate: StressCheck has built-in capabilities to automatically report solution accuracy, helping you make intelligent engineering decisions.

Fast: How long does it take to import a CAD file, mesh, apply boundary conditions, solve and assess the quality of the solution for any quantity, anywhere, at any resolution? You’ll be pleasantly surprised with StressCheck. Let us show you via a presentation/demonstration.

Efficient: The elite combination of model setup, hierarchical solutions, on-demand results and built-in error feedback makes StressCheck the leader of the pack in overall efficiency.

Reliable: For a given model StressCheck will report the associated error of approximation for any result of interest. StressCheck separates modeling errors from approximation errors, making it the most reliable FEA software in the market.

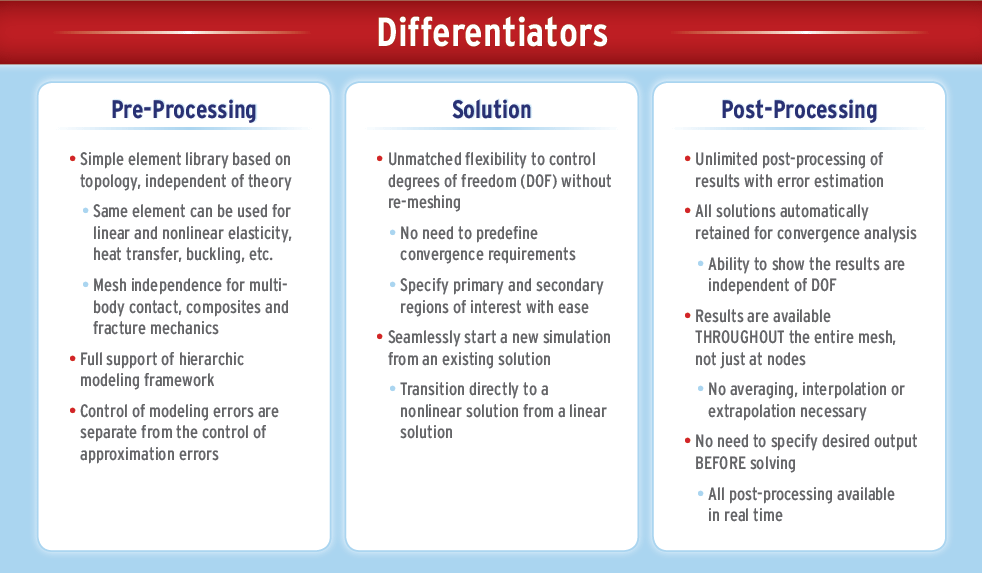

StressCheck Professional inherently contains technology differentiators which allow it to conform to the standards of Simulation Governance through its hierarchic modeling framework, model validation and solution verification capabilities:

StressCheck Professional has a broad range of industrial applications, including but not limited to:

- Fatigue & Fracture

- Residual Stress

- Crack Growth Support

- Damage Tolerance & DaDT Analysis

- Fastened & Bonded Joints (Metals/Composites)

- Laminated Composite Analysis

- Detailed Stress & Strength Analysis

- Vibration and Buckling Analysis

- Global-Local & Break-Out Analysis

“This software tool … includes an FEM-based handbook format which allows non-experts to utilize models prepared by specialists.” — Lockheed Martin

Key Features and Benefits of StressCheck Professional

Request a Trial Evaluation of StressCheck Professional

Would you like to request a 30-day, no-cost trial evaluation of StressCheck Professional? Fill out the below form (note the required fields) and submit. An ESRD sales representive will reply shortly regarding your request.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“At DST Group, we have effectively used StressCheck over the last 10 years to determine accurate stress intensity factors. The results have been used to improve our residual strength and structural life estimates for aircraft in service with the Royal Australian Airforce, including C-130, P-3C and F/A-18 A/B. We have found it to be extremely easy to use and a very versatile code with which to create parametric models.

We have recently used StressCheck to obtain improved stress intensity factor solutions (Improved stress intensity factors for selected configurations in cracked plates and Improved stress intensity factors for a single corner crack at a loaded fastener hole) for five key generic configurations. These transferable parametric results have been published externally. One specific example is the non-linear contact analysis of a cracked, filled fastener hole, with both fastener and remote plate loading.”

Dr. Manfred Heller, Head

Structural & Damage Mechanics, DST Group

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989