ESRD’s flagship software product, StressCheck, is an advanced FEA tool having numerous unique technical capabilities and inherent structure to support verification and validation (V & V). In fact, StressCheck is the first and so far only FEA software product designed to support Simulation Governance and V & V, a key requirement for the standardization & democratization of engineering simulation applications.

Our Simulation Technology

Learn more about what makes our software products well-suited for the numerical simulation of detailed solid mechanics problems.

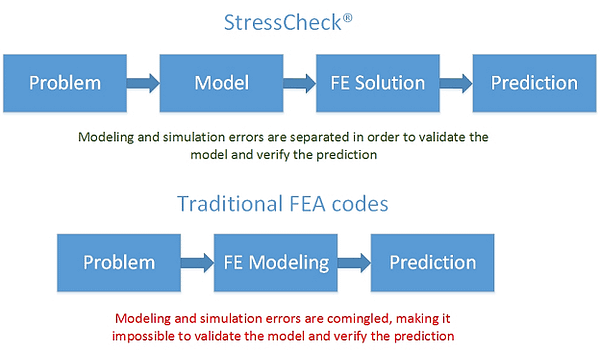

FEA + Simulation Governance = Verifiable Solutions

Our verifiable solutions are made possible by implementing the requirements of Simulation Governance. Simulation Governance controls and standardizes the simulation process much like Corporate Governance controls and standardizes the functioning of a corporation.

The yardstick that measures successful implementation of Simulation Governance is validation of the model and verification of the solution. As these terms can be misused in practice, the Dictionary & Terms glossary was developed to help us speak the same technical language.

To learn more about how ESRD’s Simulation Technology supports the tenants of Simulation Governance, refer to Simulation Governance & Management.

Our Approach to Numerical Simulation

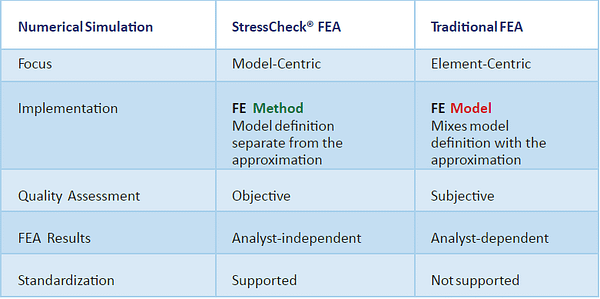

StressCheck’s Simulation Technology, or Sim Tech, is based on higher-order hierarchic finite element technology, the result of decades of R&D on numerical simulation advancements. Whereas most traditional FEA implementations are based on technology from the 1950’s and 1960’s, StressCheck’s technology incorporates more recent technological advancements.

Learn more about our unique numerical simulation technology in Brief History of FEA or view our comprehensive “Brief History of the Finite Element Method and FEA” recording:

Why is StressCheck a technological advancement when compared to traditional FEA implementations? StressCheck’s engine has inherent differentiators which support verification and validation of FEA solutions, such as a topology-based element library, full support for hierarchic modeling and hp-extensions, and mesh-independent results processing.

With StressCheck, solution degrees of freedom (DOF) are not limited to nodal output or elemental averaging; results data may be extracted from anywhere in the problem domain with proof of convergence. This means that users have tremendous flexibility and feedback during their engineering analysis workflows.

Have a few minutes? Learn more about StressCheck’s powerful and analyst-friendly implementation in the following “StressCheck Differentiators” recording:

How We Benchmark

StressCheck’s built-in model validation and solution verification methods make it ideal for benchmarking against trusted FEA results. We take the process very seriously and have compiled a library of notable benchmarks for you to reference.

Visit ESRD Benchmarks to learn more about our process, browse the library, or to request a benchmark.

What Powers Our Simulation Technology

StressCheck Professional is based on the p-version finite element method. Because the p-version is a more comprehensive implementation of the finite element method than the more traditional h-version, StressCheck Professional can be operated in both the “h-mode” (least efficient) and “hp-mode” (most efficient).

Additionally, higher-order (p-version) FEA converges at least twice as fast as the lower-order (h-version) method by using fewer degrees of freedom to get a higher solution quality. But it gets even better: with proper meshing the error of approximation decreases exponentially. A problem that takes hours to solve with a traditional h-code will only take minutes with StressCheck.

Also, StressCheck is the only FEA program in existence today which was designed for controlling the errors of both discretization and idealization.

- The errors of discretization are the errors controllable by the finite element mesh and the polynomial degree (h- or p-extensions).

- The errors of idealization are the errors associated with the restrictions incorporated in mathematical model.

This allows StressCheck to support numerical simulation like no other FEA product. For white papers, technical briefs and background information refer to ESRD White Papers in our Resource Library.

Key Benefits of Our Simulation Technology

The following are tenants upon which StressCheck’s implementation is built, and the benefits that its implementation unlocks.

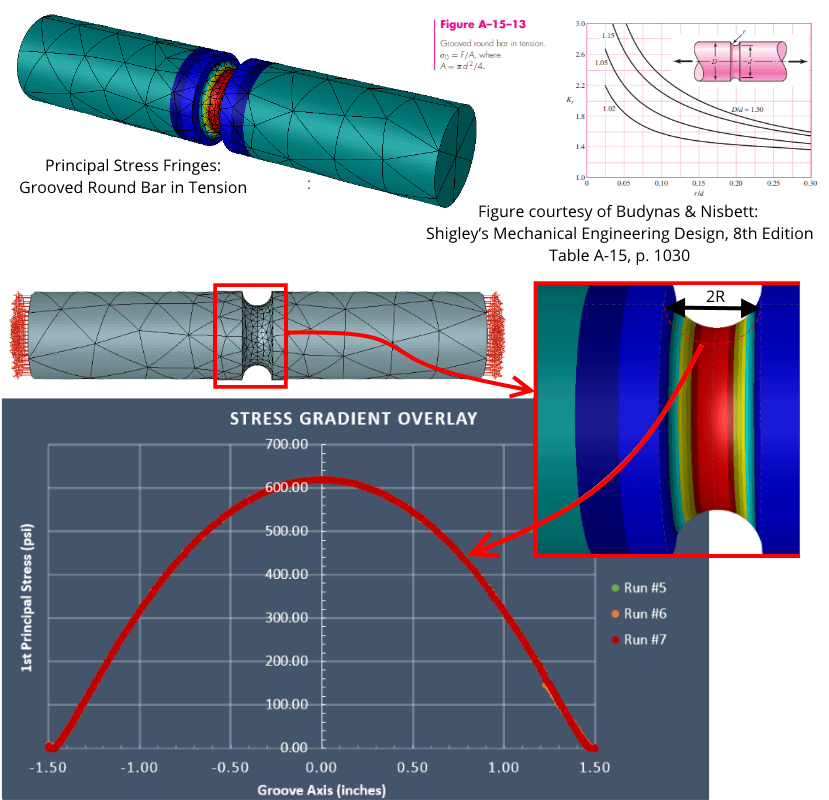

With StressCheck® the analyst typically creates one mesh, clicks a button to run an automatic sequence of solutions of increasing polynomial orders, and uses StressCheck's built-in quality assurance tools to effortlessly check for converged displacements, stresses, strains, stress intensity factors, etc. Why make it harder than it needs to be to verify that your results are of acceptable quality? In this way, analysts can focus on finding the correct model without uncertainty about the quality of the FEA approximation.

StressCheck® treats the attributes of the element separately from the topology of the element unlike any other FEA code in the industry. Switching between heat transfer and elasticity, or between linear and nonlinear elasticity, for example, does not require changing elements or remeshing. That’s what we call a true hierarchic modeling framework.

With this hierarchic modeling framework in place, our formula is simple: 1 Model + 1 Mesh + 1 Mapping + 3 Hierarchic Solutions = Verifiable FEA Results

The proper application of numerical simulation procedures requires subject expertise and expertise in computational engineering that are not common or readily available. However, it is possible to leverage both kinds of expertise through standardization of recurring analysis tasks just like handbooks and manuals have provided the expertise of specialists in applied mechanics to mechanical, aerospace, and structural engineers for decades.

The essential difference is that classical handbooks present results for parameterized problems solved by classical or empirical methods, whereas standardized CAE Handbook procedures rely on verified FEA solutions of parameterized models. This allows standardization of models that are of much greater complexity and focus to be treated as entries in a parameterized electronic handbook with greater confidence.

Need More Information About Our Simulation Technology?

Click below for FAQ’s and Selected References about our Simulation Technology, Numerical Simulation, Finite Element Modeling, Mathematical Modeling, Simulation Governance and more.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“StressCheck’s quality control features have given us the tool we need to perform detailed … bonded joint analysis with confidence that the results are accurate.”

Technical Fellow

The Boeing Company

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989