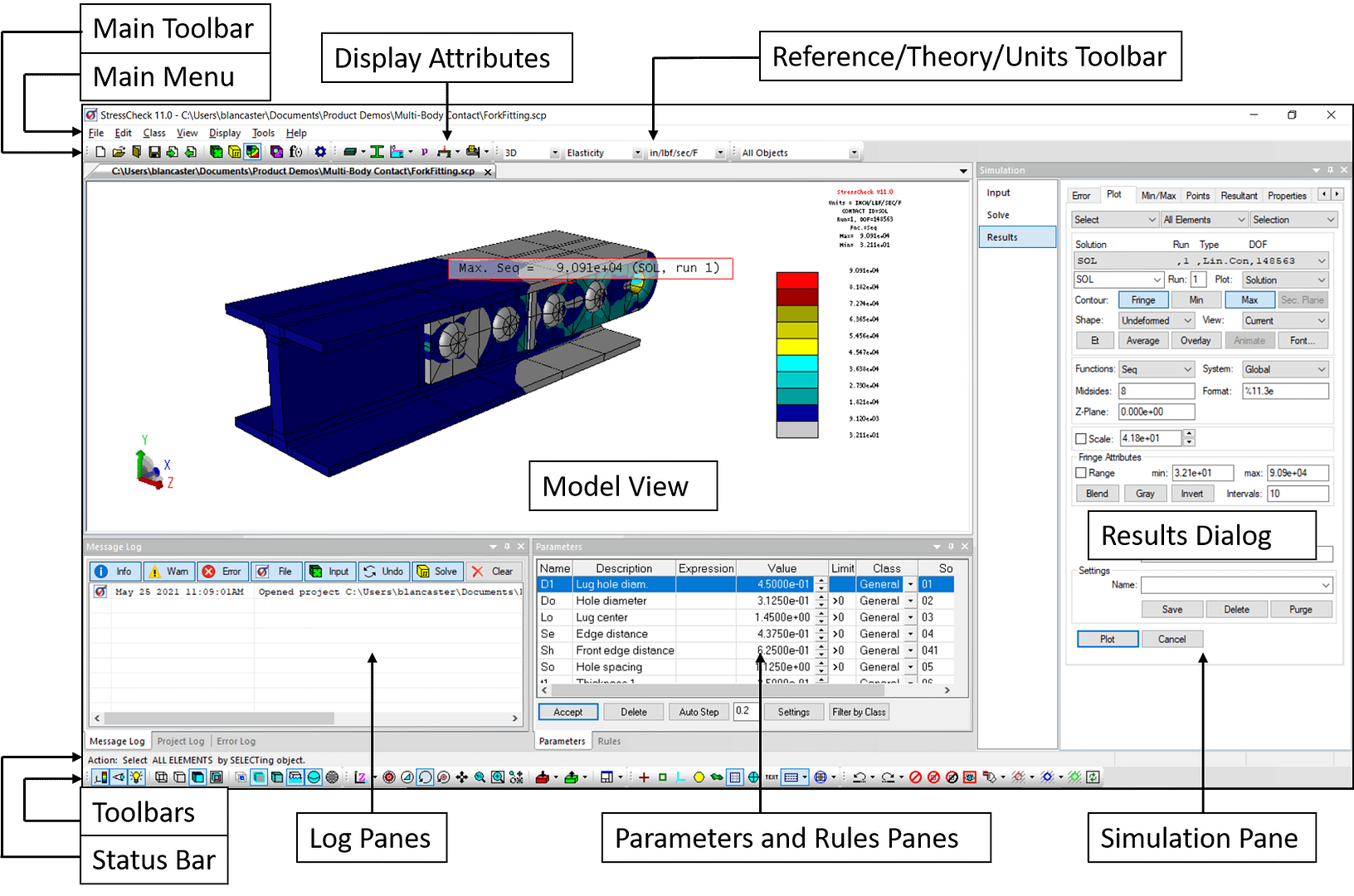

StressCheck Core is the primary building block of StressCheck Professional. It includes the 64-bit graphic user interface (GUI) and features a complete pre- and post-processor built around a parametric handbook framework that supports standardization of design and analysis processes.

With StressCheck Core, any attribute of the model (geometry, material properties, loads, constraints) can be defined parametrically, and in many cases formulae may be used as input or output.

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989