StressCheck Professional has advanced modeling capabilities in the areas of composites, fracture, residual stress and more. These are the StressCheck Advanced Modules, each module independently licensed as add-on modelers. Many of the features in these modules may even be combined together in a single model for more sophisticated FEA needs.

StressCheck Advanced Modules

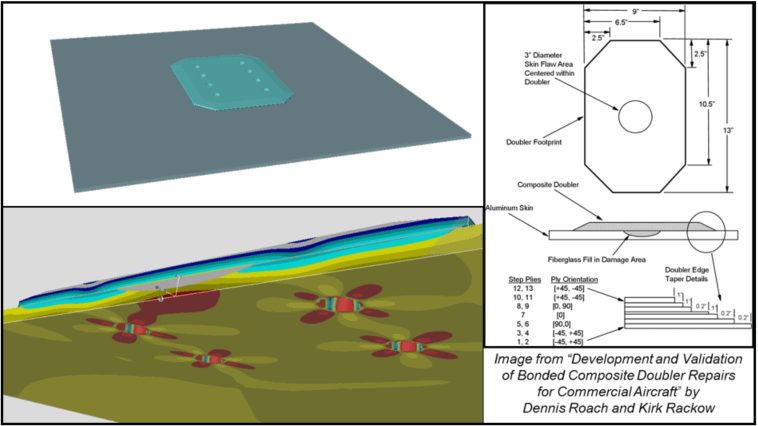

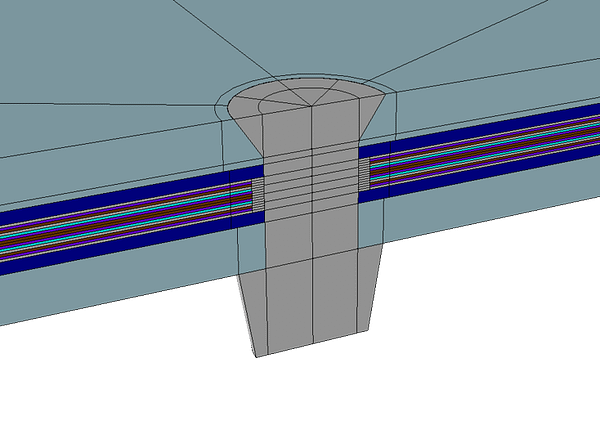

For example, an engineering application involving multi-body contact, plasticity, composites and fracture mechanics (such as for a bolted/bonded doubler repair over a cracked aluminum skin) can be efficiently simulated in StressCheck via the Composites and Fracture Mechanics modules, respectively.

3D ply-by-ply analysis with the Composites Module, enhanced through our Automatic Laminate Builder, allows you to conveniently estimate the interlaminar stresses and strains required to accurately predict interlaminar failure or assess the structural integrity of the joint.

As a result, the Composites Affordability Initiative (CAI) unanimously selected the StressCheck Composites module to “replace as well as radically improve existing industry software currently used for bonded joints.”

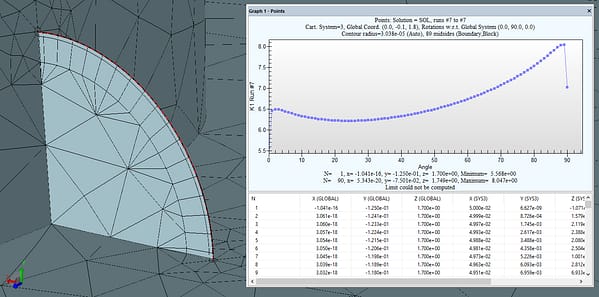

Once you solve a fracture mechanics problem with StressCheck, you won’t want to use another FEA tool for that purpose again. You will experience ease of use, realize superconvergence and receive high definition feedback information you need to guarantee the reliability and accuracy of the computed stress intensity factors (SIF) and energy release rates (ERR).

“Through [StressCheck] we are able to model, analyze and predict failure of aircraft structures and then develop crucial inspection and maintenance plans to ensure the safety and sustainability of our nation’s warplanes. Without the analysis capability provided to us through StressCheck we would not be able to provide accurate assessments of the A-10 structure to top USAF leadership.” – Southwest Research Institute Manager

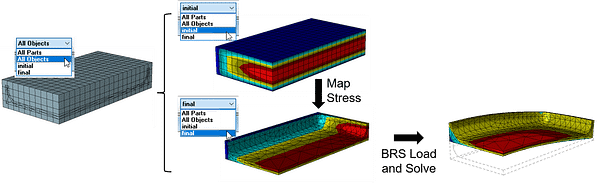

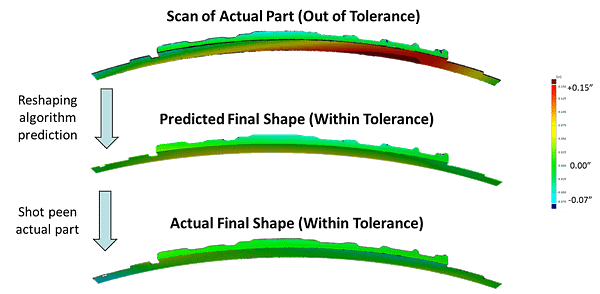

Many manufacturing or metal forming processes (such as cold working of holes) can induce residual stress throughout the volume of material. These bulk residual stresses (BRS) can significantly influence fatigue life, structural stability, failure loads, and distortion after machining. StressCheck allows such stresses, or the corresponding eigenstrains, to be included in linear analyses with industry-leading solution quality assurance procedures.

The effects of residual stresses can be beneficial, as in life extension by cold working, or detrimental, requiring reworking or rejecting manufactured parts. Reliably simulating effects of residual stresses is challenging due to extreme stress gradients. With the technology in StressCheck, representing rapidly changing stresses over short distances is a breeze.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“Through the use of StressCheck the A-10 Aircraft Structural Integrity Program’s (ASIP) Analysis Group is able to model more accurately the physics of fatigue crack propagation in critical aircraft structure. Through this tool we are able to model, analyze and predict failure of aircraft structure and then develop crucial inspection and maintenance planes to ensure the safety and sustainability of our nations warplanes. Without the analysis capability provided to us through StressCheck we would not be able to provide accurate assessments of the A-10 structure to top USAF leadership.”

SWRI Research Engineer

Southwest Research Institute

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989