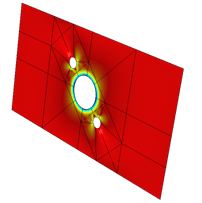

The Cold Working Solver is perfect for a quick assessment of the 2D residual stresses after cold working a single hole via mandrel insertion/removal. The modeling requirements are minimal from the analyst, with the cold work process integrated within the Cold Working Solver. All that is specified by the user is which hole is cold worked, the definition of an elastic-plastic material, the mandrel material properties and the mandrel interference.

Cold Working Solver

The Cold Working Solver is an automated Planar analysis tool that simulates the cold working process via superposition and provides the analyst with the residual state of stress resulting from pulling an oversize mandrel through a fastener hole. It is intended to provide a fast and accurate solution for when reverse plasticity is not a concern. For cases of reverse plasticity, it is recommended to use the Non-Linear Solver.

Key Features and Advantages

There is minimal input required for the solver setup:

- The hole ID to be cold worked

- The mandrel material ID

- The mandrel diametric interference

Each of these solutions is available for post-processing.

- Mandrel insertion (local plasticity around the hole).

- Mandrel removal (CW residual stress).

- Final state of stress (CW residual + applied load).

The Cold Working Solver utilizes superposition to combine the effects of the loads and constraints with the effects of the cold working operation. The following steps describe a typical cold working analysis:

- Determination of the plastic zone due to mandrel insertion.

- Determination of the residual stresses due to mandrel removal.

- The solution corresponding to any specified loads.

- The combined solution, utilizing superposition, of the residual stresses and the specified loads.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“StressCheck’s quality control features have given us the tool we need to perform detailed … bonded joint analysis with confidence that the results are accurate.”

Technical Fellow

The Boeing Company

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989