Strategies for modeling, solving & post-processing 3D multi-body contact applications in StressCheck Professional, along with implementation details & troubleshooting recommendations, will be explored.

June 23, 2020 @ 1:00 pm EST

Introduction to Multi-Body Contact in StressCheck

This webinar is now available to watch on-demand.

WEBINAR SUMMARY

In this pre-recorded 2 hour webinar we will review the scope, typical applications, model setup, best practices, quality assurance checks, troubleshooting recommendations, and algorithmic details for StressCheck's multi-body contact implementation.

WEBINAR HIGHLIGHTS

Introduction to Multi-Body Contact: Part 1

- Overview of scope and supported problem classes

- “How It Works”

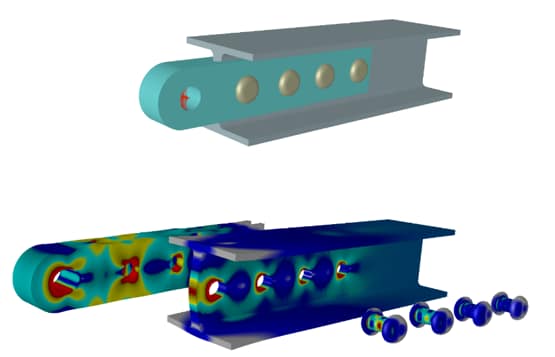

- Sample multi-body contact applications & use cases (e.g. fastened connections, fittings, splice joints, etc.)

- Setting up a model for multi-body contact & checking solution quality

- End-to-End (E2E) Demo: 3D Fork Fitting Analysis

Introduction to Multi-Body Contact: Part 2

- Implementation details & FAQ’s

- Contact algorithm: theory & application

- Recommendations & best practices

- Troubleshooting common issues

- ESRD Website Resources

WATCH THIS WEBINAR

Part 1: Overview & Applications, E2E Demo

Part 2: Implementation Details & FAQ’s

Want to Set Up an Instructor-Led Training?

Click the below button to get a quote for an on-site, off-site or web-based training course:

Request TrainingLooking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“In the case of the through crack configuration, the comparison of experimental and StressCheck derived geometry factors showed a close correlation and were an improvement to solutions provided in AFGROW at the time. Based on the results of this research, StressCheck pin-loaded lug geometry factors have since been incorporated into the AFGROW software.”

Dr. Alten Grandt

Purdue University

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989