Strategies in engineering simulation for reducing the frequency, cost, complexity, and uncertainty of aircraft maintenance inspection intervals.

June 20, 2017 at 1:00 pm EST

Durability and Damage Tolerance (DaDT) Analysis Best Practices Webinar

Advancements and best practices in airframe DaDT analysis, providing for higher resolution data and more reliable computational analyses, will be expertly demonstrated via applicable examples.

WEBINAR HIGHLIGHTS

- Simplify and sharpen DaDT fracture solutions with StressCheck FEA software.

- Overcome computational barriers to achieve high-quality stress intensities, betas and energy release rates for airframe structures.

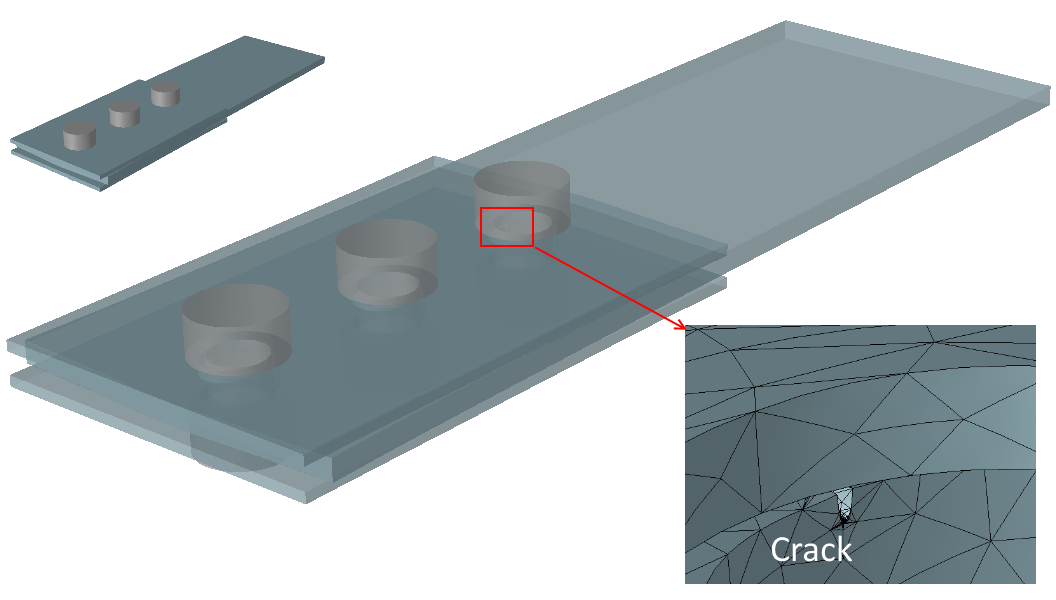

- LIVE DEMO: Combine fastened joints and corner crack effects in a single simulation.

WATCH THIS WEBINAR

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“The addition of incremental theory of plasticity in StressCheck has greatly improved our ability to accurately predict the fatigue life of joints with interference fit fasteners and cold worked holes. This ability is especially important, not only in support of maintaining aging aircraft but also in analyzing some of the new cold working techniques that have been introduced in recent years.

Prior to this implementation, analysts often relied on closed-form approximations or simple factors that were often overly conservative and sometimes even unconservative when used in life prediction. Now, not only can we more accurately predict residual stresses in these complex structural joints, but we can also do so in a timely manner given the modeling and analysis efficiency that exists with a p-version FEA code such as StressCheck.”F-15 Structures Manager

The Boeing Company

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989