The Laminate Cutout Analysis Tool (LCAT) is a Smart Engineering Simulation App providing a means to compute the strain distribution around a circular, elliptical, or racetrack cutout in a composite plate subjected to biaxial and shear loading. Additionally, LCAT determines the margin of safety for strain and the orthotropic strain concentration factor.

Laminate Cutout Analysis Tool

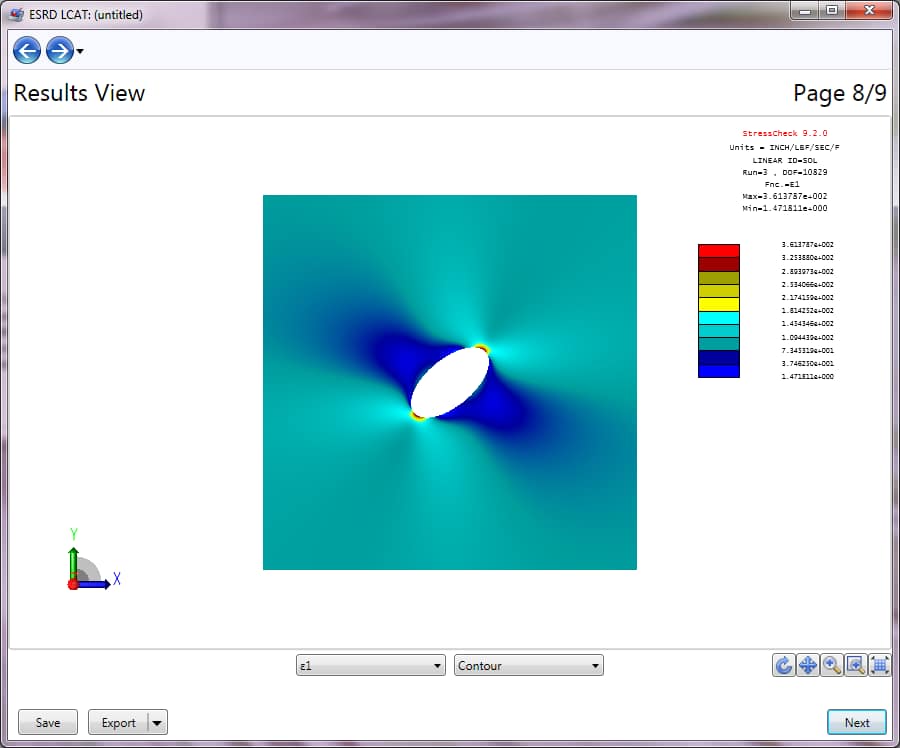

From the simple and intuitive interface, LCAT automatically builds, solves, and post-processes a Planar StressCheck finite element mesh of the desired laminated cutout shape/orientation and provides solution verification feedback.

Key Features and Advantages

- Solutions obtained with StressCheck, verified by p-extension.

- Built-in Results Viewer provides dynamic viewing of the FE mesh, the strain fringe contours and the strain directions.

- Supports US and SI units.

- Modeling approach validated with experimental results.

- Automatic computation of the laminate properties using CLPT given the lamina material and stacking sequence.

- The strain distribution around a cutout in the laminate composite being prepared for a repair.

- Margin of Safety calculation for the unrepaired cutout before sizing the repair patch.

- A simple and intuitive user interface allows input engineering data in pre-defined templates with step by step validation feedback.

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“As the United States Air Force continues to extend the service life of their aircraft the Aircraft Structural Integrity Program (ASIP) has had to refine the methods it uses to analyze and predict fatigue crack growth. Through the use StressCheck, coupled with AFGROW, we in A-10 ASIP have been able to more accurately model, predict and analyze critical aircraft structure for the A-10 and other types of structure for non-A-10 system managers. This also allows us within the A-10 to more accurately assess risk for decision makers, streamline aircraft inductions into scheduled maintenance and reduce cost for total life cycle management.”

A-10 ASIP Manager

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989