Strategies in engineering simulation for reducing the frequency, cost, complexity, and uncertainty of aircraft maintenance inspection intervals.

December 14, 2017 at 1:00 pm EST

High-Fidelity Stress Analysis for S.A.F.E.R. Structural Simulation Webinar

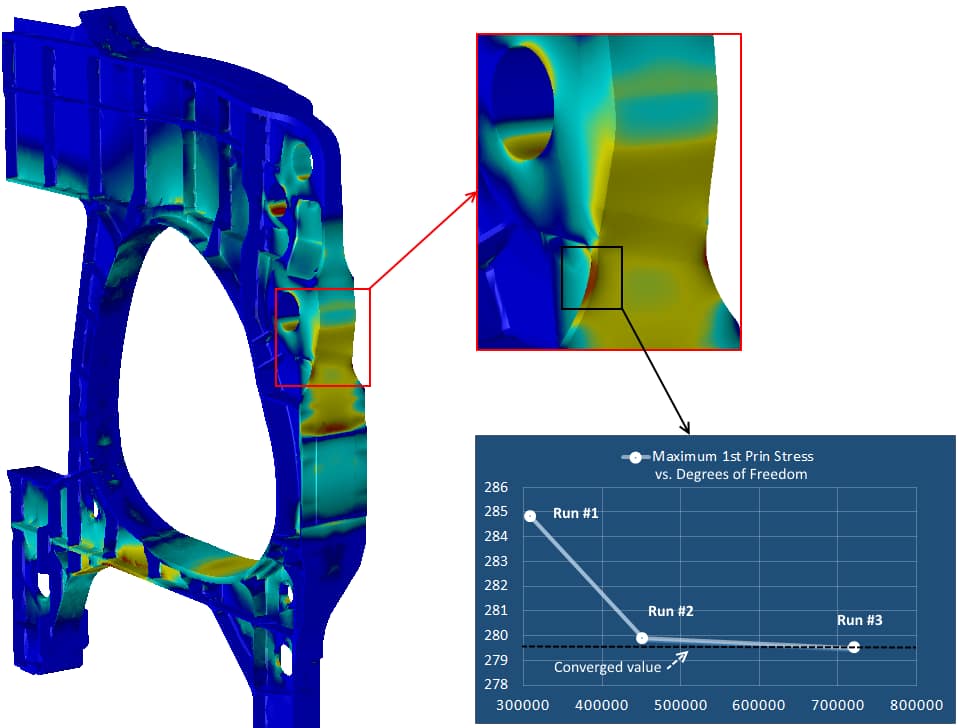

In this webinar we will share advancements in numerical simulation that make the performance of finite element analysis S.A.F.E.R. – Simple, Accurate, Fast, Efficient, and Reliable.

WEBINAR HIGHLIGHTS

- We will introduce a different approach to numerical simulation that has been developed and commercialized by ESRD which takes much of the art and craft out of finite element modeling.

- An example engineering design problem from the aviation industry, requiring accurate results around stress concentrations to meet durability requirements for a long crack initiation life, will be presented.

- LIVE DEMO: You will see a demonstration of ESRD’s StressCheck and its live dynamic results mining of any value of interest, anywhere throughout the model regardless of the mesh topology, as rapid design changes are conducted, evaluated and parametrically iterated.

WATCH THIS WEBINAR

Looking for Resources?

Recent News & Events

Quick Links

Testimonials

-

“StressCheck’s quality control features have given us the tool we need to perform detailed … bonded joint analysis with confidence that the results are accurate.”

Technical Fellow

The Boeing Company

Serving the Numerical Simulation community since 1989

Serving the Numerical Simulation community since 1989